Poly Bags / Polycube

Polymer Bags have nowadays started to become one of the most demanding types of packing from customers around the world. Features of Poly Bags Packing

We are capable to provide with you bitumen in Polybags – based on your choice – in different weight capacities.

Our Polybags are made of two layers of Polymer as well as an extra internal layer.

These Polybags can be easily melted in melting machine along with bitumen and it makes the road look a little bit more shiny.

The Future Of Polycube

POLYCUBE® PACKAGE

The POLYCUBE® Package contents the filling of the bitumen as well as the loading and transport and ends with the liquefaction at the customers place.

POLYCUBE®

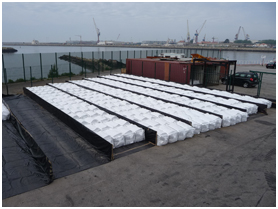

The POLYCUBE® is a special transport container that was developed for the cold transport of pasty and viscous materials in particular bitumen.

A POLYCUBE® differs considerably from the traditional Big Bag when it comes to quality, size, shape and design.

In terms of design and use of materials, the solution was aimed deliberately at the high demands imposed by the international cold transport of bitumen, to guarantee toughness, self-stabilization, and at the same time, maximum flexibility for a competitive price.

FILLING MACHINE

The Filling Machine (FM) is designed to cool down and fill paving grade bitumen into POLYCUBES®.

Bitumen supplied from storage tanks up to a temperature of 180°C is cooled down to a filling temperature just below the melting point of the packaging material. The cooling process is fully automatically controlled.

The heat quantity of the bitumen is transferred to thermal oil in a specially designed heat exchanger. Finally, the heat is given off to ambient air.

The filling of POLYCUBES® is carried out semi-automatically. The operator must place the empty POLYCUBE® under the filling head and initiate filling. After reaching the exact weight, the filling head automatically stops the bitumen flow. The operator closes the POLYCUBES®, and removes them from the filling station by forklift.

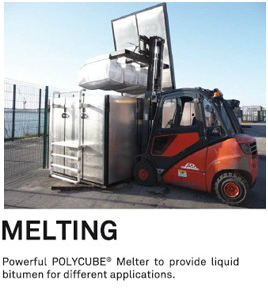

MELTER

The newly developed POLYCUBE® Melter family facilitates solutions for different applications and featuring a particular high remelting capacity. An added advantage is lower energy consumption, due to its high degree of efficiency. In full operation, the PQM is run by one operator.

POLYCUBE SPECIFICATION

Capacity

Filling quantity for bitumen (net) - 300 kg

Materials

Outer bag - PP fabric

Liner - PE

Melting point outer bag (PP) - 155oC / 311oF

Melting point outer bag (PP) - 137oC / 279oF

UV-Resistance - 6 months

Storage under roof - 12 months

Multiuse of outer bag - no

Dimensions

L x W x H (circ.) - 100 x 50 x 50 cm

Tare weight outer bag (circ.) - 1.1 kg

Tare weight outer bag (circ.) - 1.3 kg

Tare weight POLYCUBE (circ.) - 1.4 kg

Quantities

Number of POLYCUBEs fitting in a 20ft container - 80

Quantity of bitumen fitting in a 20ft container - 24 metric tons